Security

Here you will find detailed information regarding inquiries for offers, construction chronicles, as well as general project information.

Categories

-

RCDG Bydgoszcz

-

RCDG LPG in Barczewo

-

Terminal handling in Sokółka

Information about the business profile, safety measures, and procedures in the event of a major industrial accident at the premises of BARTER S.A. branch in Bydgoszcz, 8 Portowa Street

- Identification of the managing facility.

The Regional Distribution Center of LPG Gas in Bydgoszcz, ul. Portowa No. 8, is a branch of BARTER S.A. headquartered in Białystok at ul. Legionowa 28, represented by the Company’s Management Board (KRS 000283787). The facility in Bydgoszcz is led by the Manager of the Regional Distribution Center of LPG Gas in Bydgoszcz. Contact details are available on the website http://www.bartergaz.pl) - Compliance with the provisions of the Environmental Protection Law regarding the prevention of industrial accidents.

The activities conducted at the BARTER S.A. branch in Bydgoszcz involve the storage and distribution of liquefied propane, butane, and their mixtures. By the Regulation of the Minister of Development of 29 January 2016 on the types and quantities of hazardous substances present in the plant, determining the classification of the plant as one with increased or high risk of a major industrial accident occurrence (Journal of Laws of 2016, item 138), it has been classified similarly to all other plants where propane-butane gas is present in quantities equal to or greater than 200 tons, into the category of plants at high risk of a major industrial accident occurrence (so-called high-risk plants).

In addressing issues related to preventing serious industrial accidents, the facility submitted to the Commander of the Provincial Fire Service in Toruń and the Provincial Inspectorate of Environmental Protection in Bydgoszcz all required Environmental Protection documents, including the Notification referred to in Article 250 (1) of this Act and the Accident Prevention Program. These documents were accepted, positively reviewed, and approved by the competent authorities. The Safety Report was submitted to the Commander of the Provincial State Fire Service in Toruń (approved in the form of a decision) and to the Provincial Inspectorate of Environmental Protection in Bydgoszcz – positively reviewed. - 3. Description of the facility’s activities.

The bottling plant is engaged in warehousing, transshipment, and distribution of propane-butane gas and technical propane. Gas delivery to the bottling plant is carried out using tanker trucks. Upon delivery to the bottling plant, the gas is stored in four earth-banked tanks, each with a capacity of 200 m3. The gas from the tanks is transferred using pumps or compressors, via a pipeline system, to bottle filling stations and to the tanker filling station. - 4. Characteristics of stored hazardous substances.

Effects related to physicochemical properties: The substance is extremely flammable. Heating a closed container poses a risk of increased pressure and container rupture. Harmful effects on human health: Being heavier than air, the gas accumulates in lower areas of enclosed spaces, leading to unconsciousness and suffocation due to localized lack of oxygen. Contact with rapidly evaporating liquid can cause skin and eye burns (frostbite).

Environmental effects: Under normal conditions, there is no environmental threat. The liquefied gas quickly evaporates and does not pose a threat to the ozone layer. - 5. Information on main industrial accident scenarios and safety measures.

The flammable and explosive properties of liquefied propane-butane gas make issues related to ensuring the safety of the staff, environmental protection, and safeguarding company property one of the main strategic objectives of the Company’s Management Board. The primary protective and damage-limiting systems in the event of an industrial accident include:

- Identification of the managing facility.

- Fire Hydrants:

On the premises of the bottling plant, there are above-ground fire hydrants, fire hoses, and nozzles. The hydrants are strategically located to allow water supply to all installations and areas where a fire may occur. The water flow capacity of the hydrants is annually tested and meets the minimum requirements for external hydrants. Additionally, fire extinguishers are distributed throughout the bottling plant. - Sprinkler Systems:

A sprinkler system is installed in the bottle filling room, in the filled and empty bottle storage warehouse, and at the NO tanker station. The system can be activated at multiple locations on the bottling plant premises. - Safety Valves

Safety valves are evenly distributed on the technological installations and stationary tanks. In case of exceeding the set pressure, the valve opens to reduce the pressure inside the installation. The valve’s activation results in a slight gas emission and pressure drop. Safety valves are systematically checked. - Shut-off Valves

The entire gas transmission technological installation in the bottling plant is equipped with shut-off valves integrated with a detection system. Shut-off valves are designed to limit and shut off gas flow in case of emergencies. - Emergency Transfer to Backup Tanks

In case of an accident or leakage during gas transfer, there is a possibility of transferring gas to available backup tanks, including tankers. The process can be carried out using stationary pumps and compressors. - Water Tanks for Fire Protection

In case the required water flow capacity is not met, there is an inexhaustible water source for firefighting purposes in the Brda River, with the possibility of water intake at the Bydgoszcz port. - Personal Protective Equipment (PPE)

Personal protective equipment, including respiratory protective devices with isolating masks, is available on the premises of the bottling plant. Additionally, first aid kits, fire blankets, and water curtains are strategically located. - Plant Monitoring Systems

The facility is monitored 24/7 by a gas leak detection system and industrial surveillance system, allowing remote monitoring of the bottling plant premises. Monthly safety inspections are conducted as part of the monitoring process.

- Fire Hydrants:

Most of the analyzed emergency scenarios do not extend beyond the bottling plant premises. However, in the event of a BLEVE (Boiling Liquid Expanding Vapor Explosion) of a tanker and an increase in thermal radiation, it is necessary to establish a minimum protective zone to safeguard the population, with a distance of 765 meters from the NO tanker station. The analysis only concerns thermal radiation and does not include additional hazards such as overpressure effects or fragmentation. Therefore, any residential construction within the designated radius (area) is not recommended.

- 1. Methods of Warning and Public Response in the Event of an Industrial Emergency:

The bottling plant in Bydgoszcz is covered by the GOPLO system for direct communication with the Crisis Management Department in Bydgoszcz in the event of a serious industrial emergency.

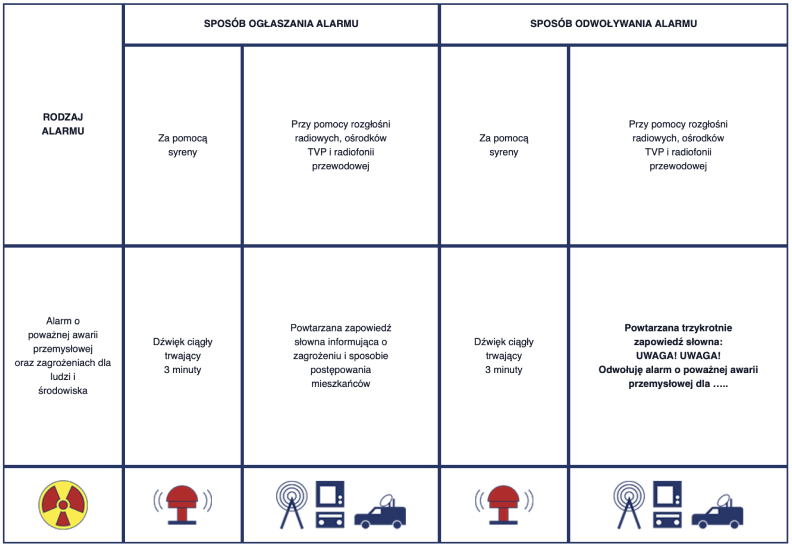

Type of alarm intended for use in the event of a serious industrial emergency:

Procedure after the alarm is announced:

- Extinguish all open flames, do not smoke cigarettes.

- Immediately cease all work, especially welding, cutting, and welding.

- Turn off gas appliances such as stoves, fans, and other unnecessary electrical devices.

- Stay calm, prevent panic, close doors and windows.

- When leaving the building, check if all users, household members have left the apartment.

- Evacuate from the endangered area to a safe place and wait for further instructions from the appropriate rescue services.

- Do not block phone lines, seek information on the local station’s website or listen to the local radio station.

Information on the profile of activities and implementation of issues in the field of prevention of major accidents

industrial in the area

Regional LPG Distribution Center in Barczewo ul. Zatorze No. 1.

1. designation of the operator of the plant.

Regional LPG Distribution Center in Barczewo ul. Zatorze No. 1, is a branch of BARTER S.A., based in Bialystok at ul. Legionowa 28, represented by the Company’s Board of Directors (KRS 000283787). The plant in Barczewo is managed by the Manager of the Regional LPG Distribution Center in Barczewo. Contact details are posted on the website http://www.bartergaz.pl)

2. implementation of regulations under the Environmental Protection Law in the field of industrial accident prevention.

As a result of its activities related to the storage and distribution of liquefied petroleum gas propane-butane and propane, the plant is subject to regulations for the prevention of industrial accidents. Due to its gas storage capacity, it has been classified as a plant with an increased risk of a major industrial accident.

Implementing the issues arising from the prevention of serious industrial accidents, the plant submitted to the Chief of the Municipal State Fire Service in Olsztyn and the Provincial Inspectorate of Environmental Protection in Olsztyn the so-called “Environmental Protection Inspectorate”. ” Notification of a high-risk plant ” and “Accident Prevention Program”.

3. Description of plant operations.

The plant handles, stores and distributes propane-butane and propane gas. “Gas” in its liquid state is stored at the site in three above-ground pressure tanks capable of holding a total of 63 tons. LPG. The product is delivered to the plant in railroad tank cars, the contents of which are poured into storage tanks, and then in the bottling plant the process of filling gas cylinders takes place, which are then distributed to customers. The plant also distributes LPG gas by tanker trucks to motor vehicle refueling stations

4 Characteristics of stored hazardous substances.

Effects related to physical and chemical properties: The substance is extremely flammable. When a closed container is heated, there is a danger of increasing pressure and bursting the package.

Harmful effects on human health: As a heavier-than-air gas, it accumulates in the lower regions of rooms, and can lead to unconsciousness and suffocation due to local lack of oxygen. Contact with rapidly evaporating liquid can cause burns (frostbite) to the skin and eyes.

Effects on the environment: Under normal conditions, there is no risk to the environment. The liquefied gas evaporates quickly. Does not pose a threat to the ozone layer.

5 Ways to warn and deal with the public in the event of an industrial accident.

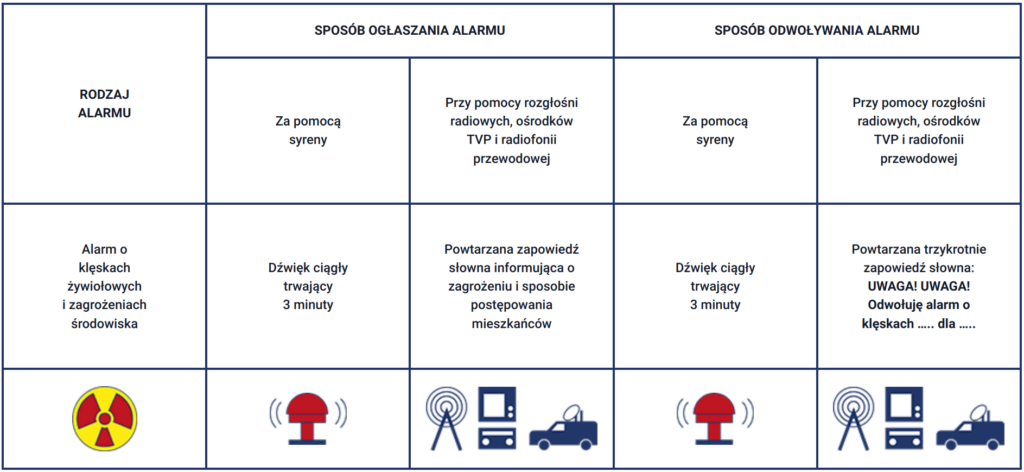

The type of alarm provided for use in the event of a major industrial accident:

How to proceed after an alert is declared:

- Extinguish all sources of open flame, do not smoke cigarettes,

- Immediately stop all work, in particular, such as welding, cutting, welding, etc.

- Turn off gas appliances-kitchens, fans and other unnecessary electrical appliances,

- Remain calm, counteract panic, lock doors and windows,

- When leaving the building, check that all users, household members have left the apartment,

- evacuate the affected area to a safe place and await further instructions from the relevant emergency services,

- do not block phone lines, look for information on the website of a local online news station or listen to a local radio station.

Information on the profile of activities, safety measures and how the public should behave in the event of a serious industrial accident on the site of the Transshipment Terminal BARTER S.A. branch in Sokolka Oś. Buchwalowo No. 2.

1. designation of the operator of the plant.

Transshipment terminal in Sokolka Axis. Buchwalowo No. 2, is a branch of BARTER S.A. represented by the Board of Directors of the Company, based in Bialystok at ul. Legionowa 28,. The Sokolka branch is headed by the plant’s Director (KRS 000283787; contact information is posted at http://www.bartergaz.pl).

(2) Implementation of regulations under the Environmental Protection Law on the prevention of major industrial accidents.

As a result of its activities related to the storage and distribution of liquefied petroleum gas propane, butane and their mixtures, as well as the storage of diesel fuel for its own use, the plant is subject to regulations for the prevention of industrial accidents. The storage capacity of the aforementioned media, classifies it into the so-called “storage”. High-risk bets.

In implementing the issues arising from the Law of April 27, 2001. – “Environmental Protection Law” the plant has developed and implemented a safety management system and submitted the following documents to the Podlaskie Regional Fire Chief and Podlaskie Regional Environmental Protection Inspector for review:

- Plant notification;

- Major industrial accident prevention program;

- Security Report;

- Internal Emergency Operations Plan;

and provided the necessary information for the development of the “External Emergency Operations Plan.”

The Podlasie Provincial Commander of the State Fire Service in Bialystok, after receiving a positive decision from the Podlasie Provincial Inspector of Environmental Protection in Bialystok, approved the “Safety Report” also evaluating positively the submitted “Notification”, “Program for prevention of serious industrial accidents” and “Internal emergency plan”.

3. Description of plant operations.

The business profile of the Company BARTER S.A. branch in Sokolka is related to the possibility of taking advantage of its geographical location on the basis of an extensive railroad siding and infrastructure allowing the reloading of goods transported by rail. The plant, as part of its business activities, is not limited to trading propane-butane gas, but is also engaged in container handling, the sale of mineral fertilizers and the distribution of coal. In addition, the site offers the possibility of shipping and storing materials such as wood and wood chips. The stored product range does not pose a risk of a major industrial accident and does not contribute to the facility’s classification as a high-risk facility.

4 Characteristics of stored hazardous substances determining the classification of the plant as a high-risk plant.

- PROPANE, BUTANE AND THEIR MIXTURES:

Effects related to physical and chemical properties:

The hazardous properties of liquefied petroleum gas propane-butane are primarily due to its susceptibility to ignition in a mixture with air, it is not among the toxic substances while it is classified as an extremely flammable substance.

Hazard statements:

H220 – Extremely flammable gas.

H280 – Contains gas under pressure; heating may cause explosion.

Effects on human health:

As a heavier-than-air gas, it accumulates in the lower regions of rooms, and can lead to unconsciousness and asphyxiation due to a local lack of oxygen. Inhalation of gas with high concentrations can cause nausea, headaches and dizziness. Prolonged exposure to gas fumes can adversely affect the central nervous system. As with all liquefied gases, contact with rapidly evaporating liquid can cause frostbite to the skin and eyes.

Environmental effects:

Under normal conditions, there is no risk to the environment. The liquefied gas evaporates quickly. Does not pose a threat to the ozone layer.

- DIESEL , DIESEL NO. 2:

Effects related to physical and chemical properties:

| Flam Liquid 3 | H226 | Flammable liquid and vapor |

Effects on human health:

| Asp. Tox. 1 | H304 | May be fatal if swallowed and enters airways |

| Skin Irrit..2 | H315 | Causes skin irritation |

| Acute Tox.4 | H332 | Harmful if inhaled |

| STOT Rep. Exp. 2 | H373 | May cause damage to organs (blood, thymus, liver) through prolonged or repeated exposure. |

| Carcinogenicity | H351 | Suspected of causing cancer |

Environmental effects:

| Aquatic Chronic 2 | H411 | Toxic to aquatic life with long-lasting effects |

5 Information on major industrial accident scenarios and safety measures.

The flammable and explosive properties of propane-butane liquefied petroleum gas make the issues of ensuring crew safety, protecting the environment and securing company property one of the main strategic goals of the Company’s management.

Basic industrial safety and mitigation systems used at the cargo terminal :

(a) a multi-layered safety and security system,

(b) ensuring full mechanical integrity,

(c) use of safety devices and installations such as:

– Gas detection system with panels set to two ranges of system response:

I. the first “warning” threshold triggers light and sound signals,

II. The second “alarm” threshold shuts down the filling equipment, closes the solenoid valves and shuts down the electricity supply.

– Mechanical exhaust ventilation that activates when a leak is detected,

– grounding system to dissipate static electricity from tanks coupled to switches that activate filling equipment,

– the use of breakaway couplings to prevent damage to the stationary installation if the tanker connected to the installation is moved,

– fixed sprinklerfire extinguishing system,

– The electrical system and equipment are adapted to work in hazardous areas,

(d) water supply system, consisting of a network of fire hydrants, a fire water tank. and supporting equipment,

(e) conducting periodic exercises with rescue entities.

The substances located at the gas handling terminal, due to their physicochemical properties, pose a threat primarily to the plant’s process plant operation and, in most of the analyzed emergency scenarios, do not threaten people and facilities outside the plant. The plant is located on the outskirts of the cities on a relatively large area of several dozen hectares. The propane-butane gas handling terminal accounts for less than 8% of the floor area of the entire plant, so the possible effects of a major industrial accident will be concentrated primarily in the plant area. However, assuming an exceptionally unfavorable combination of accident factors, one cannot exclude the possibility that the extent of the effects of the accident may affect the off-site area. In the event of a major accident, there is the possibility of releasing propane-butane gas into the atmosphere, which under normal circumstances would be diluted in the air, but under certain conditions can pose an explosive hazard.

Hypothetical emergency scenarios foresee the possibility of being affected to a significant extent by thermal radiation and overpressure waves also outside the site. It is anticipated that facilities located to the north of the plant behind Axis Road may be affected. Buchwalowo ( Railroad Street) and the nearest buildings on Railroad Street. Track.

6 Information on how to warn and deal with the public in the event of a major industrial accident at the propane-butane gas transshipment terminal.

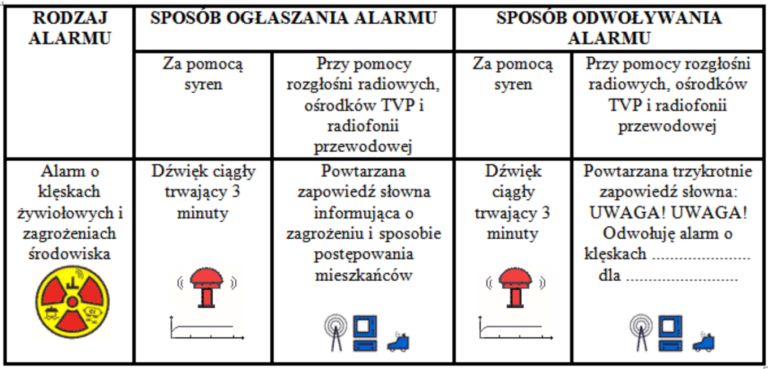

The proclamation and cancellation of an alarm at the site is signaled by the plant’s emergency siren.

– A continuous sound lasting three minutes.

– A continuous sound lasting three minutes.

Attention! The plant’s emergency siren can be activated for a few seconds for training purposes or after maintenance procedures. In order to obtain confirmation of an emergency situation at the terminal, please contact the plant service by phone No. (85) 722 95 00 or the Fire Department tel. 998.

The following table shows how the emergency services (State Fire Service) declare the alarm:

How the public should proceed after an alert :

- remain calm, extinguish all sources of fire ie. hearths, bonfires, do not smoke cigarettes,

- Turn off the gas stove, electric heating devices and other such appliances,

- Close the doors and windows,

- when leaving the building, check that all users, household members have left the facility,

- Evacuate to a safe place and wait for further instructions from the appropriate emergency services,

- try not to block phone lines, look for information on the website of a local online news station or listen to a local radio station.